We continually invest in the modernization and expansion of our machine park and tools. Our main goals are to increase overall efficiency and further improve the quality of rendered services.

Our modern fully automatic SMT assembly production line consists of a solder paste printer, two precise, high-speed SMD placers and a reflow system. We have expanded the THT assembly department with a new through-hole assembly machine.

We also use automatic wire processing machines for basic operations, such as cutting, stripping and crimping.

.

Machine Park [Electronics assembly]

Fully automatic in-line solder paste printer JUKI G-TITAN

![]() Full automatic

Full automatic

![]() Repeatability: +/- 18 um

Repeatability: +/- 18 um

![]() Maximum print format: up to 460×460 mm

Maximum print format: up to 460×460 mm

High-speed precise SMD placers (Pick&Place machines) P&P JUKI KE 2050 (chip shooter) JUKI KE 2060

![]() Efficiency: up to 240 000 placed components per day

Efficiency: up to 240 000 placed components per day

![]() Capable of using up to 160 8mm feeders at once

Capable of using up to 160 8mm feeders at once

![]() Optical and laser measurements

Optical and laser measurements

![]() Min. size of components: 0201

Min. size of components: 0201

![]() Min. lead pitch of components: 0,4 mm

Min. lead pitch of components: 0,4 mm

Reflow Soldering Oven JUKI RS 800

![]() 8-zone heating (heating zones length 3120 mm)

8-zone heating (heating zones length 3120 mm)

![]() 2-zone cooling ( cooling zones length 800 mm)

2-zone cooling ( cooling zones length 800 mm)

![]() Temperature range 20-300 degrees

Temperature range 20-300 degrees

Hybrid AOI YAMAHA YSi-12

![]() Test performance: 18ms/cm2

Test performance: 18ms/cm2

![]() Resolution for the X/Y axis: 10 µm

Resolution for the X/Y axis: 10 µm

![]() Resolution for the Z axis: 5 µm

Resolution for the Z axis: 5 µm

![]() The ability to control circuits with maximum dimensions: 600×460 mm

The ability to control circuits with maximum dimensions: 600×460 mm

![]() The ability to control ready circuits and apply paste

The ability to control ready circuits and apply paste

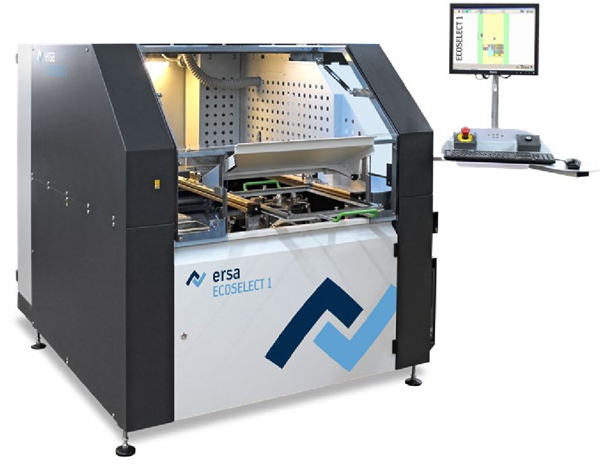

Selective soldering – Ersa ECOSELECT 1

![]() Two soldering heads capable of soldering using two types of alloys

Two soldering heads capable of soldering using two types of alloys

![]() Precise fluxing module,

Precise fluxing module,

![]() Option to preheat the PCB on both sides,

Option to preheat the PCB on both sides,

![]() Possibility of soldering panels up to 508 x 508 mm in size,

Possibility of soldering panels up to 508 x 508 mm in size,

![]() Capacity up to 600,000 soldering points per month

Capacity up to 600,000 soldering points per month

Printed circuit boards separator Maestro 2M

![]() Elimination of the problem with cracking SMD components

Elimination of the problem with cracking SMD components

![]() Titanium cutting discs

Titanium cutting discs

Soldering stations from reputable providers: JBC, Ersa, Weller

![]() 150W

150W

![]() Temperature tolerance +/- 2° C

Temperature tolerance +/- 2° C

Programming, testing and service stations

![]() Programming components and modules with dedicated tools

Programming components and modules with dedicated tools

![]() Test and inspections in accordance with client’s specifications

Test and inspections in accordance with client’s specifications

![]() Detection and elimination of any non-conformities

Detection and elimination of any non-conformities

Machine Park [Cable harnesses production]:

Automatic wire processing machine Kodera C550SZTSe

![]() Actual capacity of up to 60 000 cables per day

Actual capacity of up to 60 000 cables per day

![]() Automatic crimping of terminals on one side of the cable

Automatic crimping of terminals on one side of the cable

![]() Automatic twisting of copper wires and tinning on the other side of the cable

Automatic twisting of copper wires and tinning on the other side of the cable

![]() 100% force control of each crimp

100% force control of each crimp

![]() Adapted to thin wires from 0.03mm2 (AWG 32) and small rasters of connectors from 1mm

Adapted to thin wires from 0.03mm2 (AWG 32) and small rasters of connectors from 1mm

Automatic wire processing machine Kodera C551SZ

![]() Actual capacity of up to 60 000 cables per day

Actual capacity of up to 60 000 cables per day

![]() Automatic crimping of terminals on both sides of the wires

Automatic crimping of terminals on both sides of the wires

![]() 100% force control of each crimp

100% force control of each crimp

![]() Adapted to thin wires from 0.03mm2 (AWG 32) and small rasters of connectors from 1mm

Adapted to thin wires from 0.03mm2 (AWG 32) and small rasters of connectors from 1mm

Automatic cutting and stripping machines Kodera Casting C351 and SchleunigerMultiStrip 9480

![]() Total efficiency: 100 000 wires cut and stripped per day

Total efficiency: 100 000 wires cut and stripped per day

![]() Min. wire gauge/cross-section: AWG 28 /0,08mm2

Min. wire gauge/cross-section: AWG 28 /0,08mm2

![]() Max. wire gauge/cross-section: AWG 6 /16mm2

Max. wire gauge/cross-section: AWG 6 /16mm2

![]() Ability to cut and strip multi wired cables

Ability to cut and strip multi wired cables

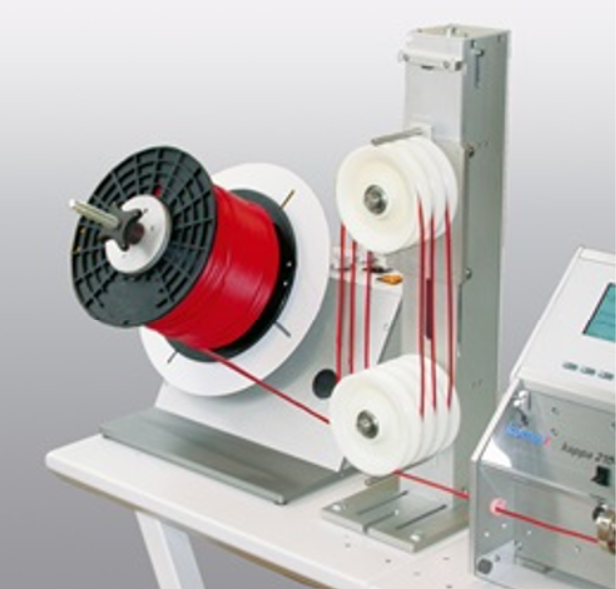

Komax ADS 115

![]() Active, compact system for smooth cable feeding, with an electric drive

Active, compact system for smooth cable feeding, with an electric drive

![]() Cable feeding at a speed of up to 3m/s

Cable feeding at a speed of up to 3m/s

![]() Improved quality of wire cutting (complete elimination of jerks on cutting machines)

Improved quality of wire cutting (complete elimination of jerks on cutting machines)

Komax Mira 32

![]() Compact model for stripping cables with electrical control.

Compact model for stripping cables with electrical control.

![]() Isolation of wires with cross-sections 0.03-3.3 mm2 (AWG 32-12)

Isolation of wires with cross-sections 0.03-3.3 mm2 (AWG 32-12)

![]() Total stripping length 1-25 mm

Total stripping length 1-25 mm

![]() Partial stripping length 2-25 mm

Partial stripping length 2-25 mm

![]() Cycle time approx. 0.3 s

Cycle time approx. 0.3 s

Printer – Hitachi Ink Jet UX Series

![]() Possibility to print any content on the entire cable (repeating the content every few cm)

Possibility to print any content on the entire cable (repeating the content every few cm)

![]() Inkjet printer – does not interfere with insulation

Inkjet printer – does not interfere with insulation

![]() Black ink

Black ink

![]() Print height 2-10 mm

Print height 2-10 mm

Applicators for terminals (more than 30 pcst) Mecal, Tyco, Hanke

![]() Side and rear-loaded

Side and rear-loaded

![]() Ability to crimp most of the terminals and connectors available at the market

Ability to crimp most of the terminals and connectors available at the market

Quality control RED PT110 – Motorized pull tester and crimp cross-section analysis stadion

![]() Thorough record of performed tests

Thorough record of performed tests

![]() Tolerance: 0,5%

Tolerance: 0,5%

![]() Ability to measure up to 1000 N tensile strength

Ability to measure up to 1000 N tensile strength

Machine Park [milling]:

CNC milling machine – CROMACHINE MR400

![]() spindle 2.2 kW, CNC milling area is 433 mm x 248 mm x 200 mm

spindle 2.2 kW, CNC milling area is 433 mm x 248 mm x 200 mm

Milling materials:

![]() Plastics (PEHD, LDPE, PC, PMMA)

Plastics (PEHD, LDPE, PC, PMMA)

![]() Wood and wood-based materials (MDF, chipboard, plywood)

Wood and wood-based materials (MDF, chipboard, plywood)

![]() Metals (Steel, aluminum, brass, bronze)

Metals (Steel, aluminum, brass, bronze)