About Company

Based on our knowledge and experience, we provide our clients the means to deliver innovative electronic solutions to the world, creating a better, brighter future. For all of us.

Every day we take up challenges and set our goals a little bit further, to improve the quality of our services and meet each and every requirement of our clients. We strive to cultivate a culture of constant improvement through optimizations in every department of the company.

We learn and develop our competencies and skills through cooperation with clients from various industries, which allows us to face increasingly more demanding projects. We strive to expand the range of our services to become a comprehensive provider for our clients. We want to offer a broad spectrum of services to help our clients to reduce the logistics necessary for finishing their projects.

The company’s history

-

2024-2025

- purchase of a new machine for applying SMT paste or glue – JUKI G-TITAN

- increase in employment of approximately 70 people

- increase of the company’s area to 1000 m2

- change of company status to a limited liability company

- development of the automatic optical control department

- planned purchase of AOI 3D and X-Ray

-

2022-2023

- Change of company location, modern new factory located in Krakow

- Establishing a mechanical department and its own tool room

- Increase in employment of approximately 50 people

- Purchase of a THT through-hole assembly machine

- Purchase of a new reflow-soldering

-

2018-2021

- Replacing the SMD line with a newer and faster one

- Employment growth (around 40 people) and company area

- Optimizing production processes, increasing efficiency and quality

- Purchase of the next necessary machines and devices to support the production

- Acquisition of AOI (Automatic Optical Inspection) device

- Implementation of new lines for SMD assembly

- Establishing a marketing department

-

2016-2017

- The next stages of the company’s development: increasing employment and increase in space production

- Implementation of a quality management system ISO 9001

- Establishing of the Purchasing Department and the Production Planning Department

- Purchase of wire processing machines

- Employment exceeds 30 people

-

2014-2015

- The need to increase the production area. Another moving to Mrozowa Street in Cracow

- Purchase of an automatic SMD assembly line

- Establishing of the Technical Department and the Quality and Control Department

-

2012-2013

- First relocation

- Focusing the company on the assembly of electronics and production of cable harnesses

- Purchase of the first production machines

-

2010

- The company was founded by Artur Wydra, who has 10 years of experience in the field of services offered by the enterprise

- Initially, the company employs one employee

Our certificates

| |

ISO 9001:2015Production in accordance with the quality management system |

Downloads

| |

WDR Elektro

|

We would like to inform you that as of 24.09.2024, the status of our company has changed to:

WDR ELEKTRO SPÓŁKA

Z OGRANICZONĄ ODPOWIEDZIALNOŚCIĄ

Christo Botewa 6

Kraków 30-798

NIP- 6793310418

WDR ELEKTRO cordially invites you to visit our stand no. 27 at the TEK day fair, Gdańsk 2025-AmberExpo Gdańsk – 11 września 2025

Blog

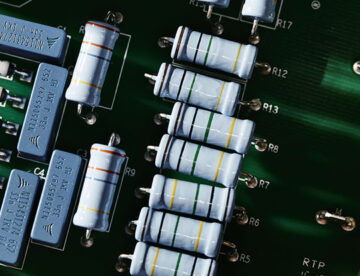

THT assembly (Through-Hole Technology), or through-hole technology, is a technology for assembling electronic components on printed circuit boards (PCB). The technology consists in inserting elements with leads through metallized holes in the PCB, and then soldering them from the other side of the PCB. Elements can be placed by hand or by machine. Soldering can…

The history of the JUKI brand. Many of you associate the name JUKI with a manufacturer of sewing machines for domestic and industrial use. As a hobby, maybe we are fans of clothing creations created at home, but professionally – the JUKI company – interests us more in other aspects. Not everyone knows that this…

Printed circuit boards are a key component of almost every electronic device. The complexity of printed circuits increases with the complexity of electronic systems. Multilayer boards offer many possibilities which are not available in the case of single-layer or double-layer PCBs. One of the most popular solutions in the world of electronics are four-layer boards,…

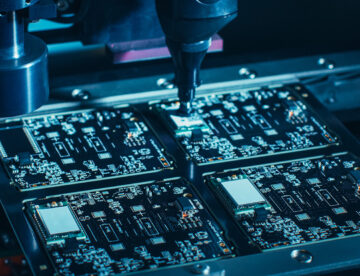

SMT assembly (surface-mount technology), in other words surface mounting, is, next to THT, the most common method of mounting elements. In this case, the elements do not have long leads passing through the holes in the PCB, but their leads are flat, equal with the base of the housing. They are placed directly on the…

Our partners

SMT (Surface Mount Technology)

SMT (Surface Mount Technology)